Flocculant Testing for Stormwater Management: Benefits and Best Practices

As our world and communities continue to expand, companies, industries, and municipalities all strive to meet and maintain strict environmental regulations while building new infrastructure and maintaining existing systems. Given the growing concern for environmental well-being, stormwater planning, inspections and compliance has become an increasingly significant part of construction. Flocculants play a key role in achieving compliance during water quality testing and treatment processes.

Various sectors, including stormwater management, mining, agriculture, construction, and wastewater treatment, often rely on chemical flocculants and/or coagulants. In an ideal world, the methods we use to treat water will always be safe, sustainable, and effective. However, testing and treating water does not have a single solution. It is the responsibility of team members in charge of testing to ensure that the flocculant being used is the most appropriate and environmentally sustainable for each job site by considering the advantages and disadvantages of each option.

In this blog, we will discuss what flocculation and flocculants are, the most common types of flocculants, and how we use them in stormwater testing and compliance. There are both natural and chemical flocculation methods, but todays blog will focus on the latter: the chemical flocculants we use to clarify turbid water in the AEC industry.

Flocculants and Stormwater Testing

What is Flocculation? What are Flocculants?

Flocculation is when you take a specific chemical– called a flocculant– and use it to reduce the “turbidity” (or cloudiness) of a liquid (often water). The flocculant binds to particles suspended in the water to form larger particles called flocs. These flocs either float to the surface (flotation) or settle at the bottom (sedimentation), making them easier to remove. Some of the benefits of flocculation include improved water clarity, removed pollutants, settled suspended soils, and a reduced need for treatment and filtration.

The chemistry behind flocculation is based on the charge of the particles present in the turbid water. Attractive forces between the particles cause them to clump together. The effectiveness of a flocculant depends on several factors, such as the weight of the molecule, the charge (+/-), and the charge density (how much of a charge a polymer chain possesses). Therefore, certain flocculants have a better time creating flocs out of certain materials, as the flocculant introduced needs to be able to bind to the particles in the water and alter them. For this reason, many flocculants– particularly synthetic ones– are also larger.

In practical terms, flocculation takes material suspended in a fluid (most often water) and creates ‘flocs’ from them, making them easier to see and remove. The particles suspended are often, but not always, sediment. Both coagulation and flocculation can be used in tandem to clarify a liquid.

Water with sediment before the chemical flocculant is added.

What is the Difference Between Coagulation and Flocculation?

You may have heard of coagulation before, especially in the context of blood (where it is often called clotting). The difference between coagulation and flocculation is that when something coagulates, it brings particles together and causes them to clump up, thickening the liquid to a solid or semi-solid state. Though similar, Flocculation is a process that settles these particles, separating them out from the main liquid host.

Ferric Chloride being used in a jar test.

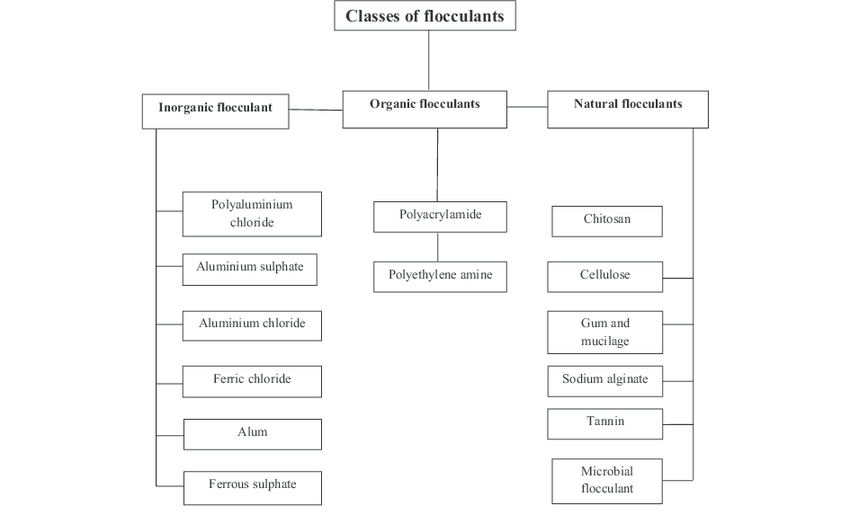

What kind of Flocculants are there?

Chemical flocculants are widely used and generally effective, but they are not one-size-fits-all. They exist in various forms, both organic and inorganic. They are primarily available as inorganic, organic, and composites. These polymers must meet specific requirements: they need to be effective, affordable, readily available, and environmentally friendly.

Some examples of inorganic flocculants that meet the requirements listed above are aluminum sulfate and ferric chloride, also known as aluminum salts and iron chloride, respectively. Another aluminum flocculants include aluminum chloride, while other iron-based flocculants can include ferric sulfate and ferrous sulfate, among others. These kinds of flocculants are the most widely used overall.

Ferric Chloride being used in a jar test.

Organic flocculants, on the other hand, are usually polymers. Recall that when we discuss the chemistry of flocculants, the charge of the flocculant is important to creating flocs. Organic flocculants are often polyelectrolytes, which carry multiple positive or negatively charged ions. This allows them to negatively affect the surface charge of and create bridges between particles– thus, the formation of flocs. Natural polyelectrolytes, including polysaccharides like cationic starch and chitosan (a type of sugar that comes from shellfish exoskeletons), are examples of organic flocculants.

Flocculant polymers also come in different forms: dry polymers, emulsion polymers, and solution polymers.

Dry polymers consist of a physical medium, such as powders or beads. On the other hand, emulsion polymers are suspended in another medium, like oil, and solution polymers are a pre-mixed combination.

Each form has unique strengths and drawbacks, with some forms being more suitable for large-scale wastewater treatment. For example, dry polymers are the most concentrated, but they often require some set-up and may not be as cost-effective. Alternatively, emulsion polymers have a shorter shelf life and require careful calculation to ensure the correct percentages are used. Solution flocculants have the shortest shelf life and can be difficult to handle and are usually used in lower-volume flocculation. Furthermore, pH, temperature, and flocculant concentration all significantly affect soil settling velocity when used in testing. For the purposes of testing turbid water in jar tests, physical mediums are often used.

Flocculant Testing and Stormwater Management

The use of flocculants is not standardized across the United States, but numerous legal bodies have guidelines in place for flocculant usage as a part of stormwater management. For example, the North Carolina Department of Transportation (NCDOT) utilizes flocculants alongside other sediment control measures, such as wattle barriers, sediment basins, and rock ditch checks. Maintaining dosage guidelines and ensuring that large-scale use of flocculants does not negatively affect the environment are key factors in leveraging flocculation in turbidity control. Some of the more common flocculants, such as the previously mentioned aluminum sulfate, come with concerns that they will negatively impact the environment if used in too high dosages.

To determine which flocculant is best suited to a job, professionals often start with a jar test: a method of determining which chemical flocculant is suitable to treat the turbidity of the water at a construction site.

What is a Jar Test?

A flocculant jar test is when an individual manually tests different flocculants on a sample of water portioned into individual containers to see which flocculant is best suited for clarifying the water. Basically, it’s a snapshot into what a larger-scale effort to apply the flocculant may look like. As one of the first steps towards mitigating turbidity, the jar test is a key element in determining which flocculant is most suited for a specific body of water, waste stream, or other water runoff source. Once a jar test is conducted, larger-scale testing can be conducted to confirm the effectiveness of the flocculant on the water source.

All wastewater and runoff are unique in its composition, so what works for one job site may not work for the next. Jar testing is beneficial because it allows for stormwater testing professionals to determine not only which flocculant is most suitable for the site, but also because it allows for them to determine things such as the pH, filtration, and chemical load of the water sample and subsequent flocculant needs. Without the jar test, it is difficult to determine the best method for mitigating turbid water!

Photo of a jar test, with the sediment clearly settling at the bottom of the jar.

The Importance of Flocculant Testing in Construction Stormwater Management

As with all things, the use of flocculants comes with both advantages and disadvantages. Because of the variation and lack of consistency across job sites, one of the natural challenges that flocculant testing poses is its inconsistency. Not properly accounting for and testing for variance in a water source may result in the improper selection or dosing of flocculants. Elements present in the water may also disrupt flocculation, resulting in reduced effectiveness. Flocculants also require proper agitation, distribution, and storage methods to be effective. Flocculants that are not protected from heat or direct sunlight, for example, may lose much of their functionality.

Furthermore, certain chemicals used in flocculation can be toxic if implemented incorrectly. The impact a flocculant might have on organic creatures or plants within an ecosystem must also be accounted for so they do not disrupt or sicken the wildlife that inhabit a body of water. However, with regulation and correct applications, flocculant treatment is significantly less likely to contaminate water sources. For this reason, toxicology limits are available for flocculation products to ensure that they are not improperly used.

Overall, it is important to recognize the potential risk flocculants present, but also the numerous benefits they provide to stormwater testing and management.

Conclusion

Heatwaves, intense drought, heavy rain, and even hurricanes are becoming increasingly common. By investing in sustainable parks, we are taking a proactive step in combating these climate challenges. Sustainable parks not only enhance urban quality of life—they provide critical environmental benefits to communities, such as improved air quality, reduced ambient temperatures, and effective stormwater runoff management. By thoughtfully integrating ecological design principles, these parks help preserve biodiversity, protect natural habitats while providing ample opportunity to educate communities and inspire a sense of stewardship. The investment in sustainable parks is an investment in the future, ensuring that urban spaces remain livable, vibrant, and resilient for generations to come.

Summit’s Stormwater Planning and Compliance Background

Summit’s Stormwater Planning and Compliance department is dedicated to partnering with our clients to provide assistance with their compliance initiatives related to construction stormwater and erosion and sediment control, whether they be developers, contractors, government entities, or even private investors. Our team of experts is equipped to handle any task related to Stormwater Compliance, including developing project-specific Stormwater Pollution Prevention Plans (SWPPP), lot-level erosion and sediment control plans, pre-purchase site assessments, and post-review recommendations. We are highly effective at BMP selection and implementation, field compliance reviews, project documentation and permitting audits, and NPDES inspections.

As a nascent department, our service offerings and capabilities will continue to grow. We look forward to the near-future, where we’ll be able to offer Environmental Site Assessments, Lot-specific Custom Erosion Control Plans, Drone reconnaissance, and more.